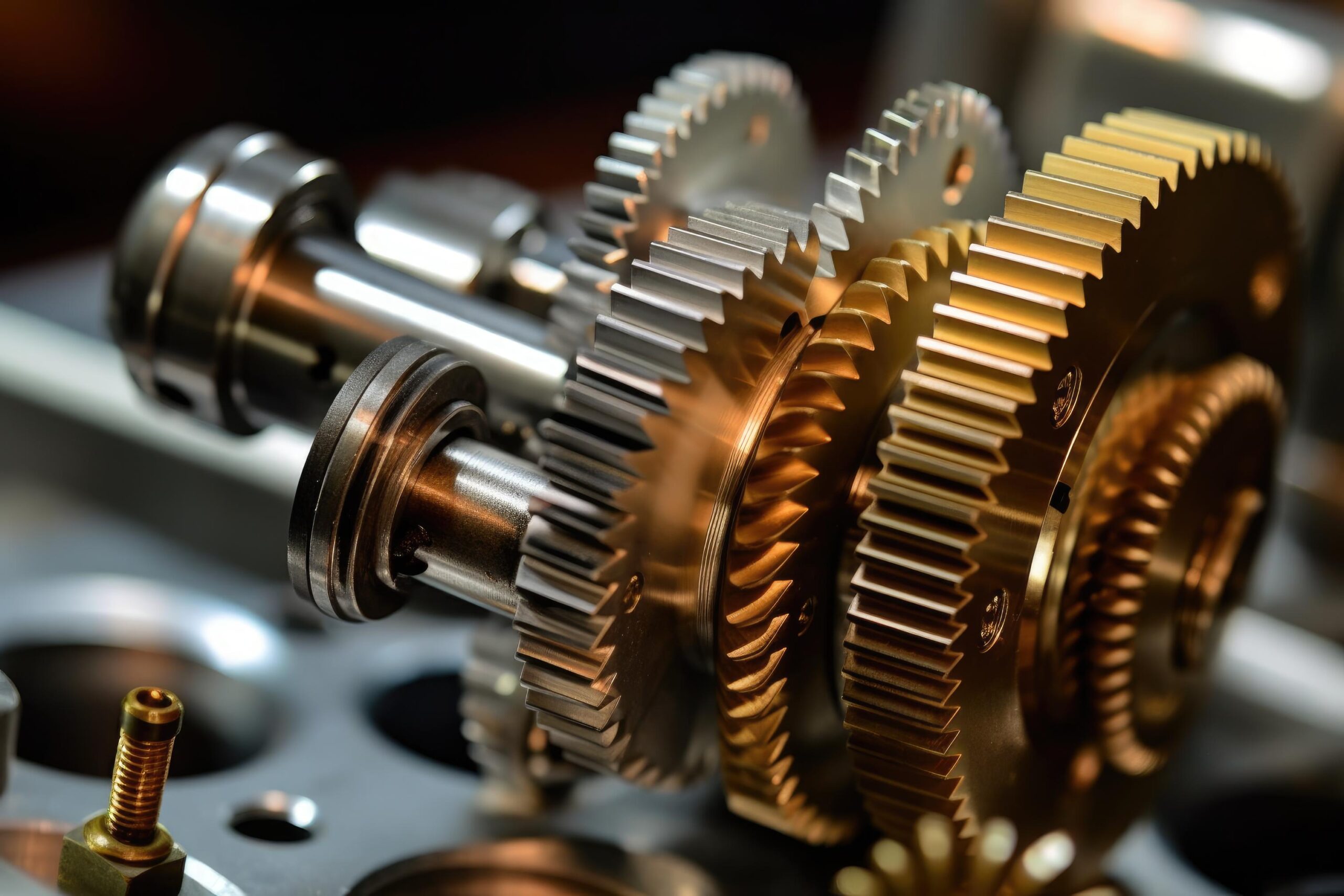

Home Blogs Advancements in Gear Shaping Technology Blog March 14, 2024 In the fast-evolving landscape of manufacturing, gear shaping technology continues to undergo significant advancements, revolutionizing production processes across industries. At DM Technologies, we pride ourselves on staying at the forefront of these innovations, integrating cutting-edge technologies to enhance the precision, efficiency, and reliability of gear manufacturing. *Introduction:* Gear shaping is a critical process in the production of gears, crucial for ensuring smooth operation and optimal performance in machinery and equipment. Recent technological advancements have introduced sophisticated solutions that streamline production, improve product quality, and reduce operational costs. *Key Technological Innovations:* *Precision Gear Shaping Machines:* Discuss advancements in CNC-controlled gear shaping machines that offer high accuracy and repeatability, catering to complex gear geometries and varying production demands. *Automation and Robotics:* Explore the integration of automation and robotics in gear shaping processes, enhancing speed and consistency while minimizing human error. *Advanced Tooling and Materials:* Highlight developments in tooling technologies and materials used in gear shaping, such as carbide inserts and high-speed steel, to improve cutting performance and durability. *Benefits and Applications:* – *Improved Efficiency:* How these advancements reduce setup times, increase throughput, and optimize resource utilization. – *Enhanced Quality Control:* Benefits in terms of tighter tolerances, smoother surface finishes, and reduced scrap rates. – *Cost Savings:* The impact on overall operational costs through increased productivity and minimized downtime. *DM Technologies’ Approach:* As a leader in the gear industry, DM Technologies embraces these advancements to offer state-of-the-art gear shaping solutions. Our commitment to innovation and quality ensures that our customers benefit from the latest technological developments, achieving superior performance and reliability in their gear manufacturing processes. *Conclusion:* In conclusion, advancements in gear shaping technology represent a pivotal leap forward in modern manufacturing. At DM Technologies, we are dedicated to leveraging these innovations to empower our clients with cutting-edge solutions that drive efficiency, quality, and competitiveness in the global market. Previous PostNext Post